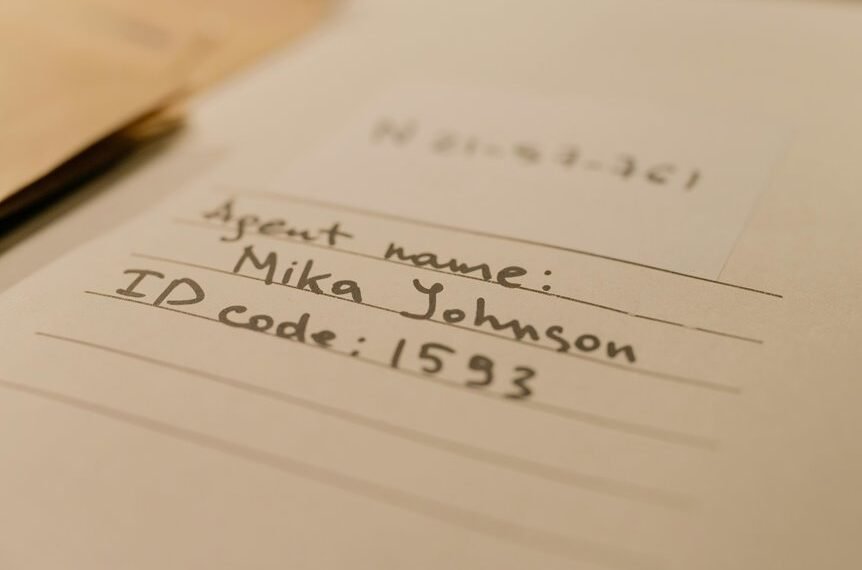

The Controlled Numeric Traceability Sheet serves as a vital tool in the manufacturing sector for items 900907501, 695913431, 616363333, 612261702, 120578225, and 3332341502. It enhances traceability and compliance, ensuring materials and components are meticulously monitored. This systematic approach fosters data accuracy, crucial for identifying defects. However, the implementation process and best practices surrounding such a sheet warrant further examination to fully understand its impact on quality and operational efficiency.

Importance of Traceability in Manufacturing

Although often overlooked, traceability in manufacturing plays a crucial role in ensuring quality control and regulatory compliance.

It facilitates effective quality assurance by tracking materials and components throughout the supply chain. This process empowers manufacturers to swiftly identify defects, enhance product safety, and optimize operations.

Ultimately, robust traceability fosters transparency, enabling businesses to respond adeptly to market demands and uphold consumer trust.

Overview of the Controlled Numeric Traceability Sheet

While ensuring comprehensive tracking of products and components, the Controlled Numeric Traceability Sheet serves as an essential tool in manufacturing environments.

This sheet facilitates numeric tracking of various items, promoting data accuracy throughout the production process. By documenting essential information, it empowers manufacturers to maintain oversight, streamline operations, and enhance accountability, ultimately fostering an environment of reliability and informed decision-making.

Key Features and Benefits

A multitude of key features and benefits characterizes the Controlled Numeric Traceability Sheet, making it an indispensable asset for manufacturers. Notably, it ensures numeric accuracy, eliminating discrepancies in data.

Additionally, traceability benefits empower organizations to monitor and verify processes effectively, enhancing accountability. This comprehensive tool streamlines operations, supports compliance, and fosters a culture of transparency, ultimately leading to improved efficiency and product quality.

Implementation and Best Practices

Implementing a Controlled Numeric Traceability Sheet requires careful planning and adherence to best practices to maximize its potential benefits.

Effective implementation strategies include defining clear objectives, ensuring data accuracy, and training personnel thoroughly.

Regular audits and updates of the sheet are essential to maintain compliance and efficacy.

Conclusion

In conclusion, the Controlled Numeric Traceability Sheet stands as a cornerstone in manufacturing, ensuring that organizations can effectively track and manage their materials. By enhancing traceability and compliance, it enables companies to nip potential issues in the bud, ultimately driving product safety and operational efficiency. Implementing this tool not only supports regulatory adherence but also fosters a culture of accountability and continuous improvement, setting the stage for long-term success in an increasingly competitive landscape.